TECHNICAL SPECIFICATIONS

AVAILABLE OPTIONS:

- C60 Hot Stamp (Lot/Date Coding)

- Missing Hot Stamp Imprint Check

- Integrated Thermal Printer (Lot/Date, Bar Code and Graphics)

- Dataflex or Similar Lot/Date Code Printer

- Clear, Metalic or Color Label Sensor

- End to end Transfer Plates

- Infeed and outfeed Conveyor Extensions

- Adjustable Tilt for Tapered Bottles

- Feed Screw

- Stainless Steel Raised Bed Sanitary Conveyor (Factory installed only)

- Push and Press Attachment

- 3-panel, 4-panel or 5-panel Labeling Attachments

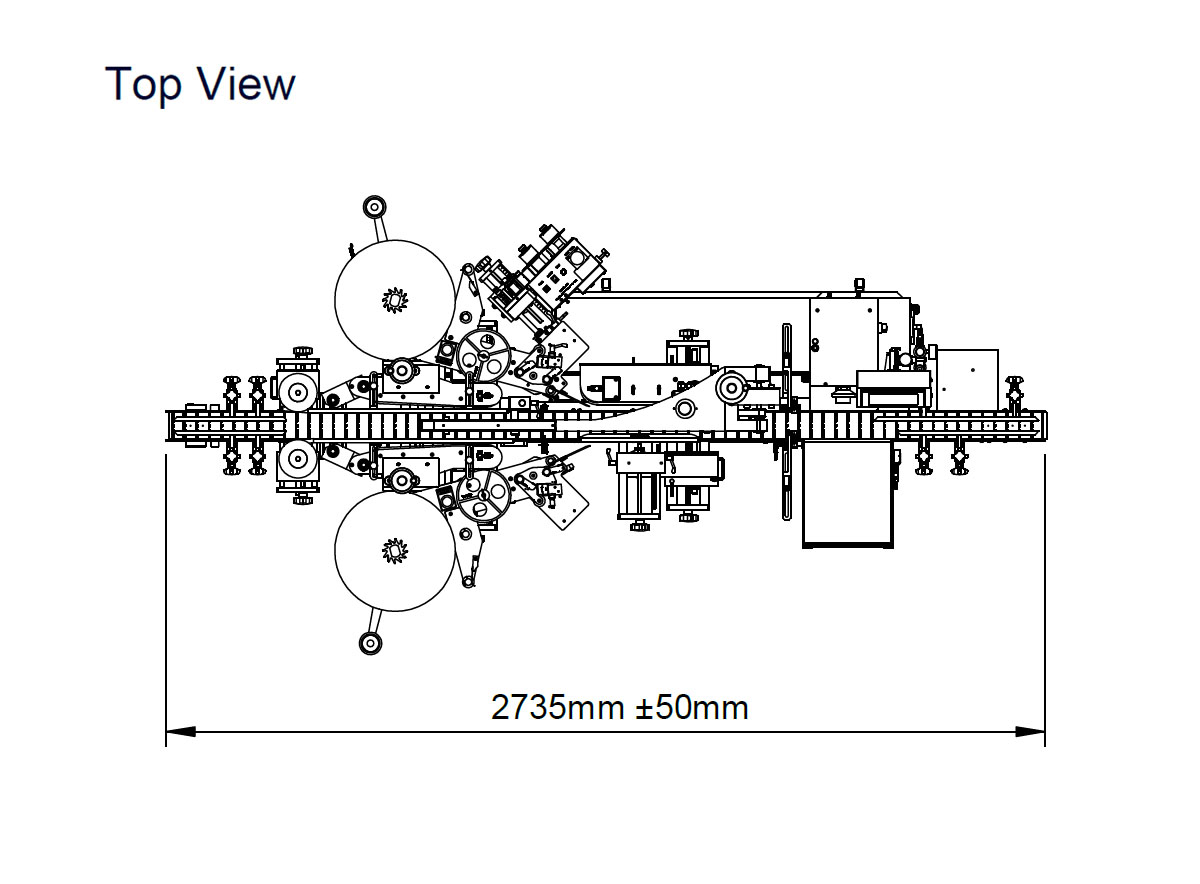

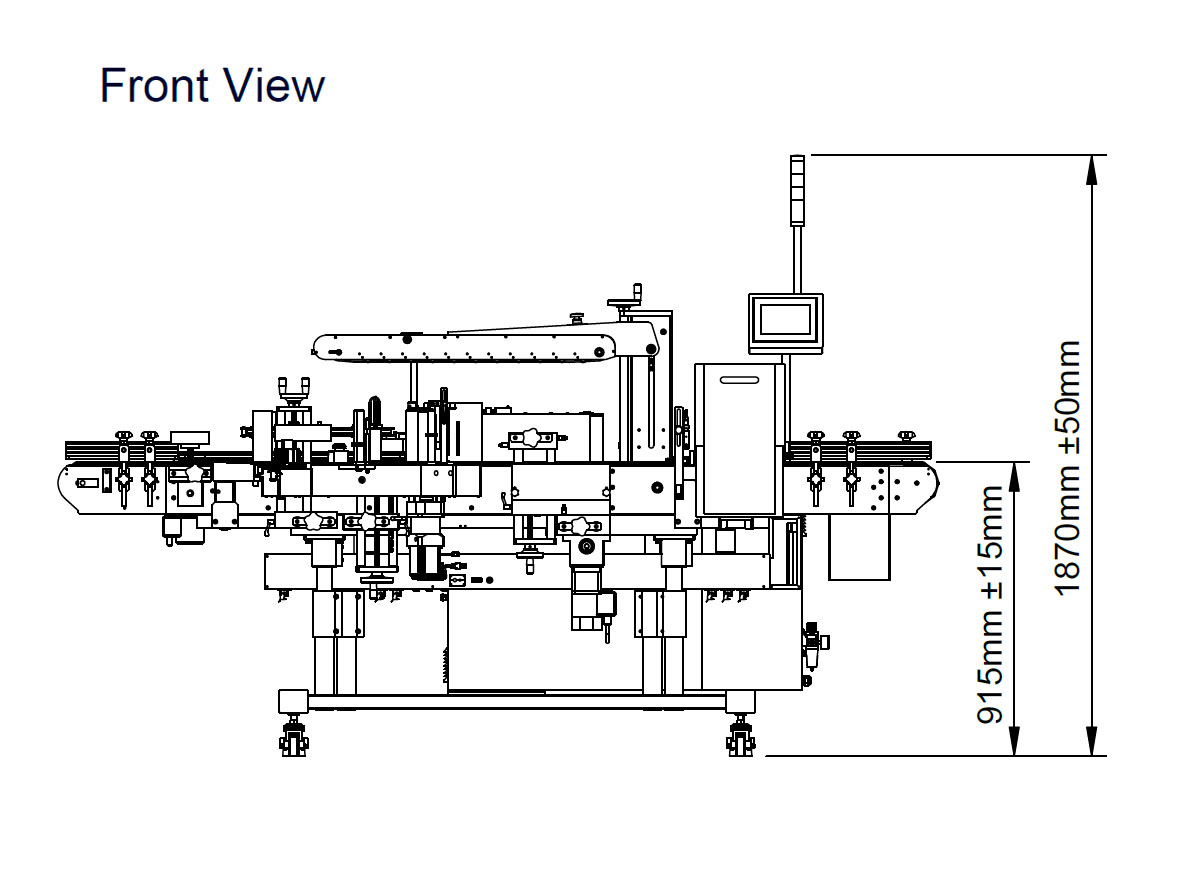

MACHINE LAYOUTS:

The dimensions shown are for standard machine. The conveyor can be extended: the length may var y based on selected options. This machine can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.

All CVC labelers include our patented Self Set™ software which utilizes a high frequency encoder for extremely easy setup and wrinkle free labeling at the touch of a button.

Technical data contained in this material are not binding and may be subject to change without prior notice.